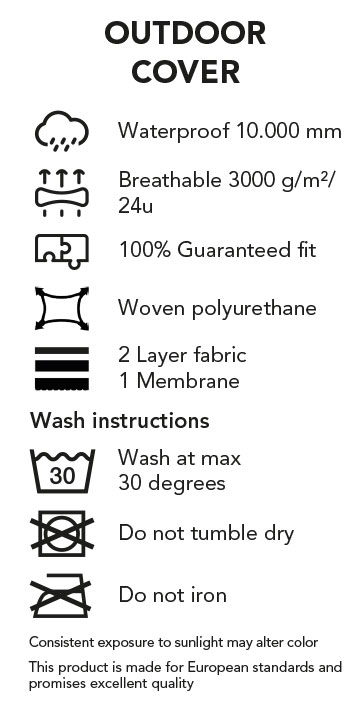

Material properties of the Star Cover outdoor stretch coverStar Cover outer covers are made of a 3-layer woven thermoplastic polyurethane. The nanotechnology that is used in weaving the polyester fibers makes it possible to apply a waterproof and breathable TPU membrane . The finish of the Star Cover outdoor cover is with a Teflon (TPTFE) water-repellent coating. So not only a membrane, but also a coating contribute to the water resistance of 10,000 mm . This means that the cover is completely waterproof in the rain, but is less resistant to horizontal pressure. In combination with the breathability of 3000 grams per m2 per day , the Star Cover cover is the perfect solution for your vehicle. The cover is therefore extremely breathable so that any condensation and rising moisture will be diverted. A completely waterproof material, which is even waterproof under water, is not breathable and is therefore less suitable for the car cover. Because the fabric is woven in 2 directions with super technology, this is 2-way stretch . This means that the material is slightly stretchable, which improves the fit and the cover does not compromise on the protection of the car. The material density of the outer cover is 280-290 grams per m2, which ensures that the cover is extremely strong, but remains manageable in weight and size. The breathability of the cover is 5000 grams per m2 per day. Which stands for very high breathability, the highest in its segment and very good protection against condensation.

280-290 g / m2 material densityStar Cover car cover is manufactured with a material density of 280-290 grams per m2 . The cover is extremely strong, but very handy in weight and the size remains limited. The cover has a UV resistance of 30 UPF . The Star Cover cover filters Ultra Violet light with a protection factor of 30 UPF, a very good protection during long-term storage in the sun. The car cover filters UV rays and ensures that they cause as little damage as possible to the car, this however ensures that the cover will discolour over time, but the cover retains its UV-resistance. The cover basically has the color of the raw materials, but the cover gets a color by means of pigment paint. This color stretches into the fibers, but does not make the fibers unnecessarily stiff, this method of dyeing has the possible disadvantage that the cover can discolour after exposure to UV light. |

|

Water resistance (waterproofness) index

How much water pressure can the material take, and what is the consequence?

Water resistance 0 mm

Does not protect against moisture, the moisture runs directly through the material.

Water resistance 0 - 1000 mm

This material is slightly water-repellent, but certainly not waterproof. This has the disadvantage that it offers no protection against rain or other liquids. The advantage, however, is that it has a very high breathability in the highest category.

Water resistance 1000 - 5000 mm

This material is waterproof against rain, but cannot withstand any kind of horizontal pressure. The material leaks due to the sustained pressure on flat surfaces such as a hood or on the roof. The disadvantage is that this material offers very limited protection against rain. On the other hand, the advantage here, too, is the breathability of the highest category, i.e. good protection against condensation and rising moisture.

Water resistance 5000 - 15000 mm (Star Cover cover)

Use of this material makes the Star Cover cover completely waterproof in the rain and resistant to many forms of pressure. Only at very high, sustained pressure, for example from long-term exposure to rain and wind, can the material begin to leak. This material has the right balance between waterproofness and breathability (3000 gr / m2 / d), which is a great advantage against condensation and rising damp . Disadvantage: the cover lets water through under prolonged or extreme use. This is also a wear-sensitive coating, with prolonged use the cover can be treated again by the customer with a Stimex Waterproof - Spray teflon coating in order to restore the waterproofness to the required level.

Water resistance 15000 - 30000 mm

Completely waterproof material, which remains waterproof even under the most extreme pressure. This material remains waterproof even with shallow immersion. The disadvantage of this material is that it is not breathable and therefore offers no protection against condensation and rising moisture. On the other hand, the material is virtually impermeable to water.

Water resistance> 30000 mm

This is only for solid, non-porous materials. These materials never leak without breaking or deforming. Disadvantage: not breathable so no protection against condensation and rising moisture. Advantage: does not allow water through even under water.

Breathability index

The breathability expressed in the number of grams of moisture that can pass through the material per square meter within 24 hours. Either condensation and moisture that can disappear under the cover.

Breathability <800 g / m2 / d

Offers low breathability and closes the car completely, there is a great chance that condensation will remain under the material.

Breathability 800-3000 g / m2 / d (Star Cover cover)

Good breathability, ideal for the outer covers. This allows for the right balance between waterproofing and breathability.

Breathability> 3000 g / m2 / d

Very high breathability, whereby condensation and moisture generated under the cover are well diverted. Within 24 hours, approximately 5000 grams per m2 of moisture is evaporated, which minimizes the risk of damage.

UV protection index

How much harmful UV radiation does a material filter?

UPF <15

Offers limited protection against ultra violet light and can cause visible damage to objects covered under the material.

UPF> 15.20

Offers good protection and absorbs significantly more than UPF <15 materials.

UPF> 25,30,35 (Star Cover cover)

Offers very good protection and is often used outdoors.

UPF> 40

Offers excellent protection and filters most of the Ultra Violet light that reaches the material, so it lets through very limited. Very suitable for outdoor use.

Condensation

Condensation occurs because water vapor comes into contact with an object (car) which is colder than the air in the environment. In this case, the moisture hits the cold surface, which creates small droplets on the surface. This effect is enhanced because metal cannot buffer condensation in any way. Every car suffers from condensation unless it is in a room where the climate can be fully controlled (heating & ventilation). To even better counteract the effect of condensation, we recommend airing the cover and car once a month.

Rising moisture

This problem is also called rising damp and is caused by ground moisture evaporating and striking the surface of an object as condensation.

TPU stands for thermoplastic polyurethane.

TPU is a waterproof and breathable membrane that is an intermediate product of rubber and plastic. It has good elasticity and high strength index. The material has physical properties unmatched by other materials in terms of water resistance (withstands a water pressure of 10,000 mm). TPU is an environmentally friendly polymer.